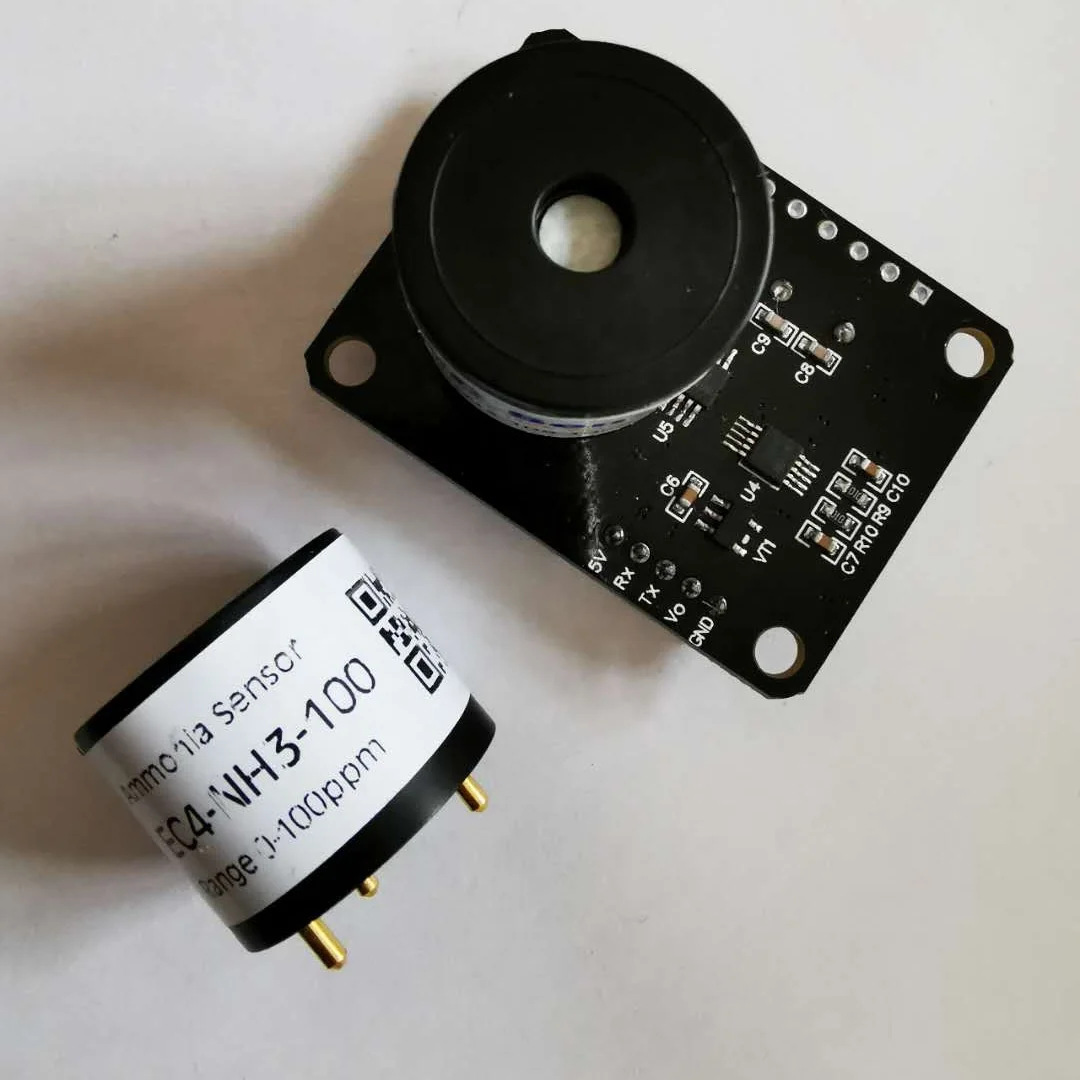

စင်ဆာသည် လုပ်ဆောင်မှုအီလက်ထရိုဒ်၊ တိုင်းတာမှုအီလက်ထရိုဒ်နှင့် အကူအီလက်ထရိုဒ်ဟူ၍ အီလက်ထရိုဒ်သုံးခုပါဝင်သည်။ ကိုးကားအီလက်ထရိုဒ်သည် တည်ငြိမ်သော အလျော်စီးပွားကို ပေးစွမ်းပြီး လုပ်ဆောင်မှုအီလက်ထရိုဒ်နှင့် ချိတ်ဆက်ထားကာ လုပ်ဆောင်မှုအီလက်ထရိုဒ်တွင် ဖြစ်ပေါ်သော အလျော်စီးပွားနှင့် ၎င်း၏ ပြောင်းလဲမှုများကို သိသာစွာ တိကျစွာ တိုင်းတာနိုင်စေသည်။

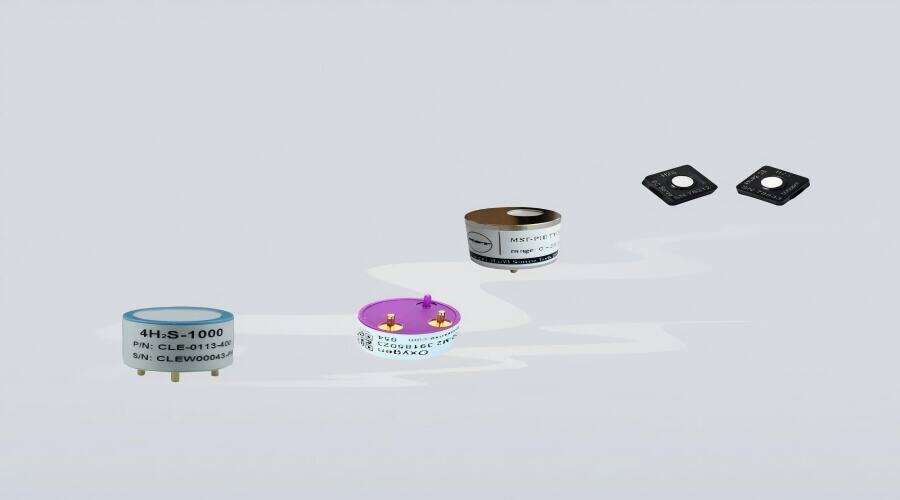

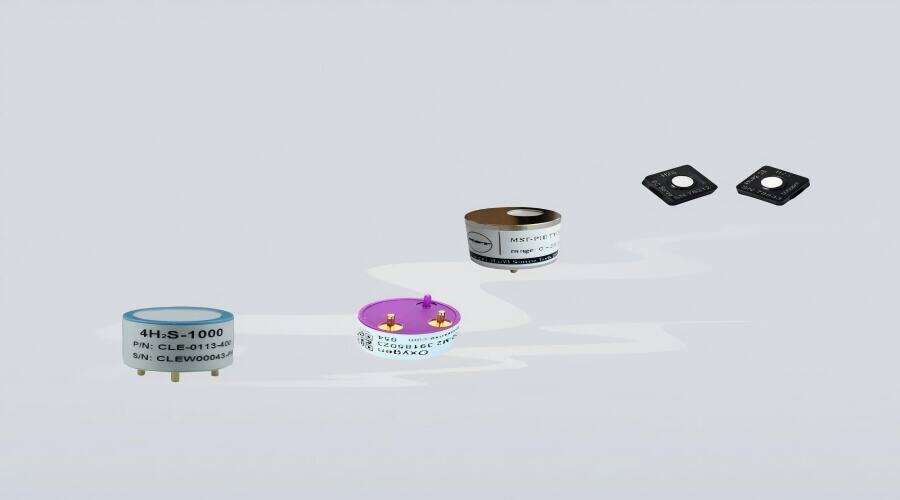

အီလက်ထရိုဓာတ်ကွဲစင်ဆာများကို ဓာတ်ငွေ့တစ်မျိုးတည်းကိုသာ တိုင်းတာရန် အဓိကရည်ရွယ်၍ ဒီဇိုင်းထုတ်ထားပြီး ဓာတ်ငွေ့တစ်မျိုးတည်းသာ ရှိသော ပတ်ဝန်းကျင်တစ်ခုတွင် ဦးတည်ထားသော ဓာတ်ငွေ့၏ ပါဝင်မှုပမာဏကို တိုင်းတာခြင်းကို ဆိုလိုပါသည်။

ဓာတ်ငွေ့တစ်မျိုးတည်းကို တိုင်းတာရာတွင် ကယ်လီဘရေးရှင်းပြုလုပ်ပုံမှာ တိုင်းတာမည့် ဦးတည်ဓာတ်ငွေ့၏ စံဓာတ်ငွေ့ပါဝင်မှုပမာဏကို အသုံးပြု၍ စင်ဆာကို ကယ်လီဘရေးရှင်းပြုလုပ်ခြင်းဖြစ်သည်။

ဓာတ်ငွေ့များကို တိုင်းတာရာတွင် သတိပြုရန် အချက်များ .အတိုင်းအတာမြင့်မားသော ဓာတ်ငွေ့များ၏ သက်ရောက်မှုမှ ဆိုးကျိုးများ ဖြစ်ပေါ်လာနိုင်ပါသည်။ အတိုင်းအတာမြင့်မားခြင်း သို့မဟုတ် ဖိအားပေးထားသော ဓာတ်ငွေ့ကို လေဝင်ပေါက်ဆီသို့ တိုက်ရိုက်ညွှန်းပါက ဓာတ်ငွေ့သည် ဆင်ဆာ၏ အတွင်းပိုင်းသို့ အတိုင်းအတာကြီးမားစွာ စိမ့်ဝင်နိုင်ပါသည်။ ထိုအခါ အလုပ်လုပ်သော လျှပ်ကူးစက် (working electrode) သည် အချိန်တိုအတွင်း ဓာတ်ငွေ့အားလုံးနှင့် တုံ့ပြန်နိုင်ခြင်း မရှိနိုင်သလို၊ ဖိအားကြောင့် ဓာတ်ငွေ့သည် ကိုးငှားလျှပ်ကူးစက် (reference electrode) အတွင်းသို့ စိမ့်ဝင်ကာ အချက်ပြမှုကို အပြုသဘောမှ အနုတ်သဘောသို့ ပြောင်းစေနိုင်ပါသည်။ အတိုင်းအတာသည် အများဆုံး ဆက်တိုက် ထုတ်လုပ်နိုင်သည့် စွမ်းရည်ကို ကျော်လွန်ပြီး ဓာတ်ငွေ့ကို ကာလရှည်ကြာစွာ ထည့်သွင်းပါက ဒုတိယအကြိမ် ပုံမှန်တိုင်းတာမှုကို ပြုလုပ်ရန် အနည်းဆုံး ၁၀ နာရီကြာ ပြန်လည်နာလန်ထူရန် လိုအပ်ပါသည်။

၅။ စံဓာတ်ငွေ့စမ်းသပ်မှု သို့မဟုတ် ချိန်ညှိမှုအတွက် ml/မိနစ် ၃၀၀ အလျင်နှုန်းဖြင့် မိနစ် ၃ အထိ ဆက်တိုက်လေဝင်ပေးရန် လိုအပ်ပါသည်။ ချိန်ညှိစဉ်အတွင်း လေဝင်ပေါက်သို့ ဓာတ်ငွေ့ကို တိုက်ရိုက်မထုတ်ပေးဘဲ အဓိကလေဝင်ပေါက်၏ ၉၀ ဒီဂရီထောင့်ဖြင့် ဘေးဘက်လေဝင်ပေါက်ကို အသုံးပြုပါ။ ထိုသို့ပြုလုပ်ခြင်းဖြင့် စင်ဆာသည် ပျံ့နှံ့သွားသည့် အခြေအနေ (diffusion state) တွင် လည်ပတ်နိုင်ပြီး လေစီးကြောင်း၏ တိုက်ရိုက်သက်ရောက်မှုကို ရှောင်ရှားနိုင်မည်ဖြစ်သည်။

အပူပြင်းသော သတင်း

အပူပြင်းသော သတင်း